Budget-friendly Lift Repair Near Me: Professional Specialists at Your Service

Wiki Article

Diving Into the Globe of Elevators: Common Problems Faced by Various Lift Systems

As we navigate via the vertical transport systems of modern structures, lifts stick out as an indispensable component of our every day lives. Nonetheless, behind their smooth procedure lies a globe of detailed mechanisms that can sometimes come across challenges. From hydraulic elevators to grip systems and machine-room-less styles, each lift type features its set of typical issues. Recognizing these challenges is vital for guaranteeing the smooth performance of these vital systems. Allow's check out the intricacies that underlie the operation of elevators and the possible concerns that can occur, clarifying the elaborate internet of lift systems.Hydraulic Lifts

Hydraulic lifts, often preferred for low-rise structures, make use of fluid stress to control the motion of the lift cars and truck (lift repair companies). This device entails a hydraulic pump pushing oil right into a cyndrical tube, triggering the lift to relocate the desired direction. While hydraulic elevators are recognized for their smooth and quiet operation, they do include their very own set of typical problemsOne widespread trouble with hydraulic elevators is oil leak. In addition, concerns with the control system, such as faulty shutoffs or a malfunctioning pump, can cause disturbances in the lift's motion.

Normal upkeep and prompt repair work are necessary to ensure the smooth performance of hydraulic lifts. By dealing with these typical concerns proactively, structure owners can decrease downtime and make sure the safety and security and performance of their upright transportation system.

Traction Lifts

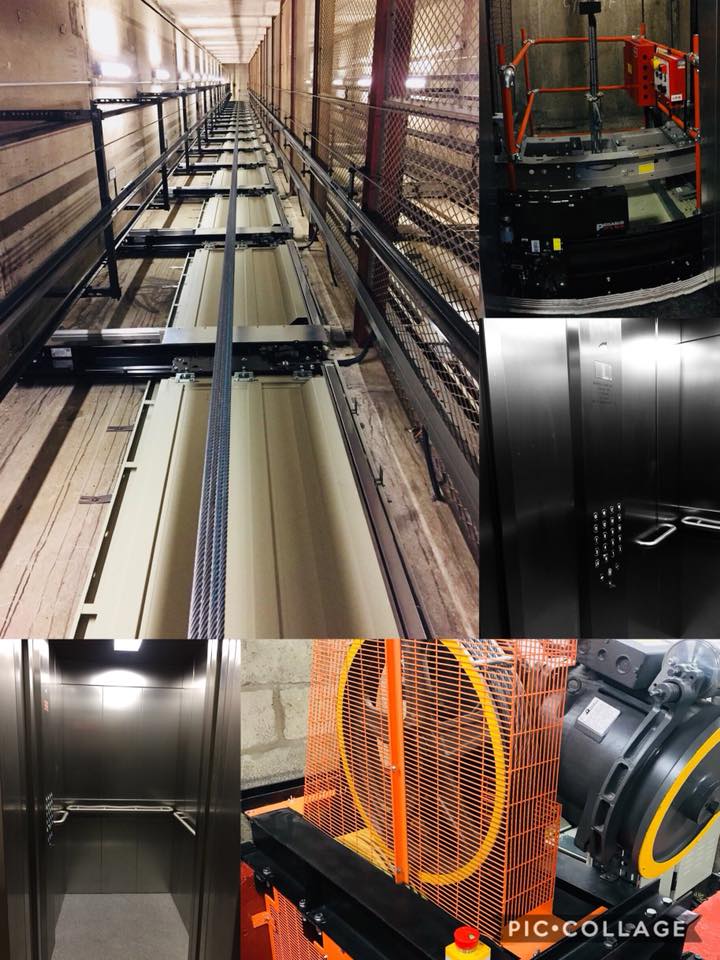

When thinking about upright transportation systems in structures, one more usual kind other than hydraulic elevators is the traction elevator. Grip lifts operate utilizing a system of ropes and counterweights that relocate the elevator car by clutching onto the hoist ropes. This device enables smoother and faster upright transportation compared to hydraulic systems.One of the typical concerns faced by grip elevators is rope wear. The continuous activity of the ropes within the grip system can bring about deterioration in time, possibly creating the lift to breakdown or come to be unsafe for use. Regular examinations and maintenance of the ropes are vital to ensure the elevator's proper performance and safety and security.

An additional issue that traction lifts may run into is connected to the control system. Troubles with the control system can lead to issues such as erratic movement, delays in reaction times, and even total shutdowns. Routine testing and upkeep of the control system are critical to avoid such problems and ensure the lift's integrity.

Machine-Room-Less (MRL) Elevators

Among the key components of MRL lifts is the portable gearless grip device that is installed within the hoistway. This equipment efficiently drives the elevator automobile without the need for bulky equipment located in conventional traction lifts. Additionally, MRL elevators commonly use a counterweight system to balance the vehicle, more improving their power efficiency.

In spite of their benefits, MRL elevators might encounter difficulties associated with repair and maintenance because of the constrained room for tools installation. Availability for servicing elements within the shaft can be restricted, requiring specialized training for service technicians. Proper upkeep timetables and regular assessments are important to ensure the continued smooth operation of MRL elevators.

Overloading and Weight Limit Issues

Straining and weight restriction concerns are important issues in elevator operations. Lift suppliers style raises with particular weight capabilities to ensure traveler safety and security and devices longevity.When elevators are overloaded, it places extreme pressure on the electric motor, wires, and other components, potentially causing breakdowns or break downs. Safety and security systems such as sensing units and overload sensors are in area to stop lifts from relocating if they identify excess weight. Additionally, surpassing weight limitations can bring about boosted power usage and wear and tear on the lift system.

To mitigate straining issues, building managers need to prominently show weight limits in lifts and enlighten owners on the importance of adhering to these limitations - lift repair companies. Normal upkeep checks by qualified professionals can additionally assist make certain that elevators are operating within secure weight specifications. By dealing with overloading and weight limitation concerns proactively, structure proprietors can enhance lift safety and efficiency

Electrical System Failings

Exceeding weight limitations in elevators can not just lead to mechanical concerns but also possibly contribute to electrical system failings within the lift facilities. Electrical system disabled platform lifts prices uk failures are a critical concern in elevator procedure, as they can trigger unanticipated closures, breakdowns, or also safety dangers.Additionally, power surges or fluctuations in the electric supply can additionally interrupt the lift's operation, affecting its performance and safety and security. These electric disturbances can damage delicate lift elements such as control board, motherboard, or sensing units, resulting in system failings. Regular maintenance and inspections are crucial to determine and attend to potential electrical problems immediately, guaranteeing the safe and efficient procedure of elevator systems. By adhering to weight limits and carrying out regular electrical system checks, building proprietors can reduce the danger of electric failures in lifts.

Final Thought

Hydraulic lifts, commonly preferred for low-rise buildings, utilize fluid pressure to regulate the activity of the lift vehicle.When considering vertical transport systems in structures, another typical type aside from hydraulic elevators is the traction lift. Traction lifts run using a system of ropes and weights that move the elevator auto by clutching onto the hoist ropes. Unlike typical elevators that need a different maker room to house the devices, MRL elevators integrate many of the elements within the shaft, getting rid of the requirement for a committed equipment room.In final thought, lifts deal with usual concerns such as hydraulic malfunctions, traction system failings, and electrical system issues.

Report this wiki page